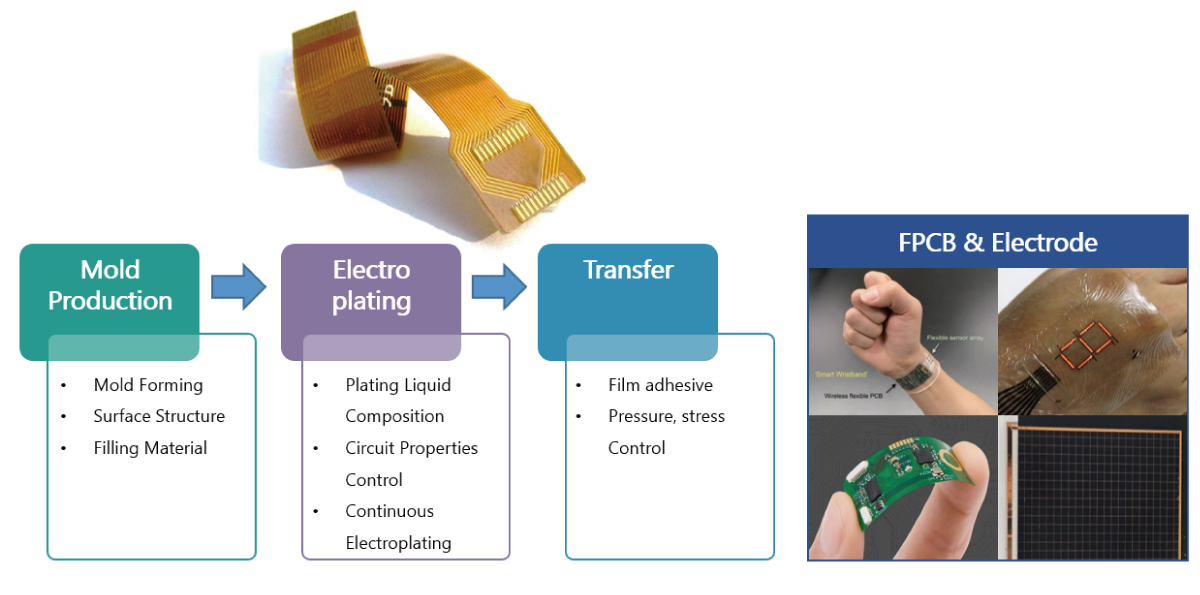

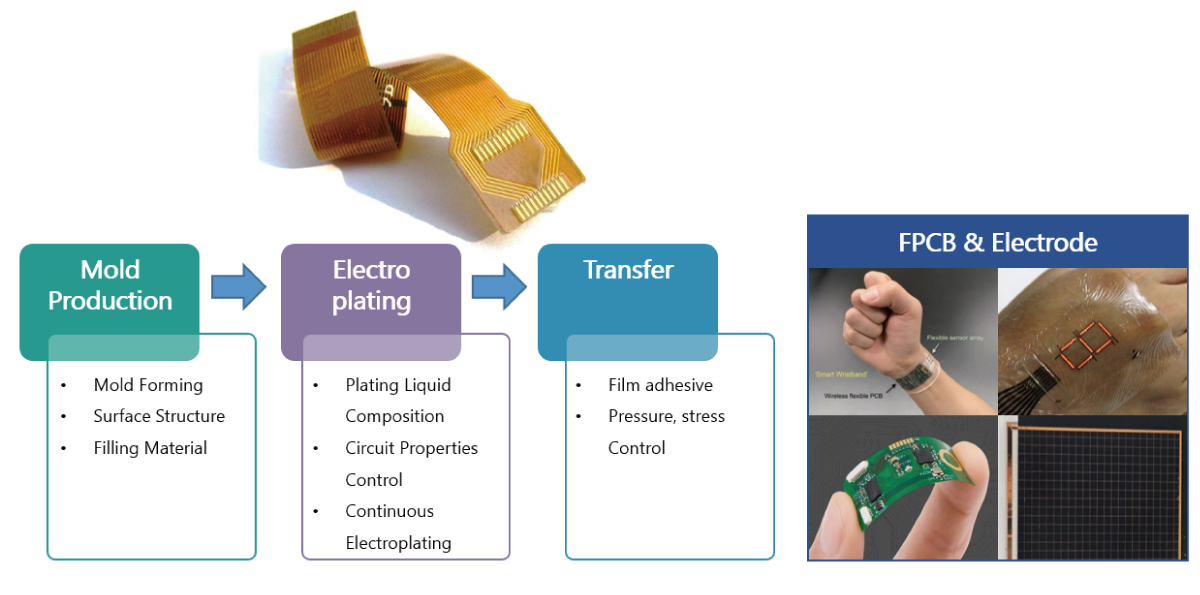

MPTP Technology (Micro Pattern Transfer Printing)

Samwon Act Co., Ltd.'s unique technology that can be produced by applying various copper foil thicknesses and various types of films to various insulating films using MPTP process.

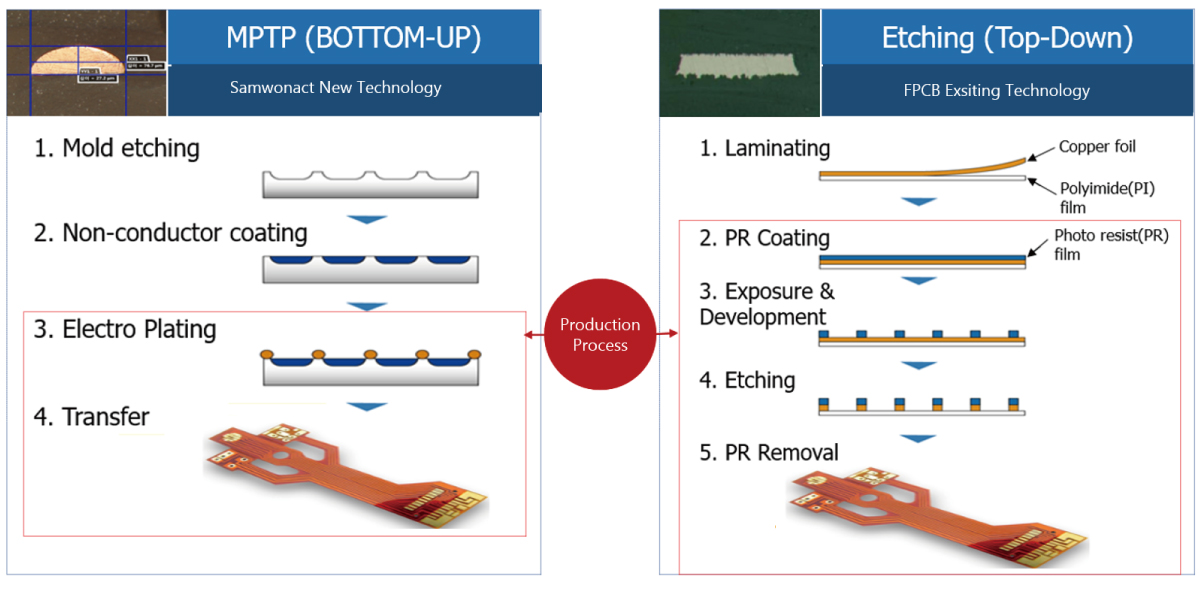

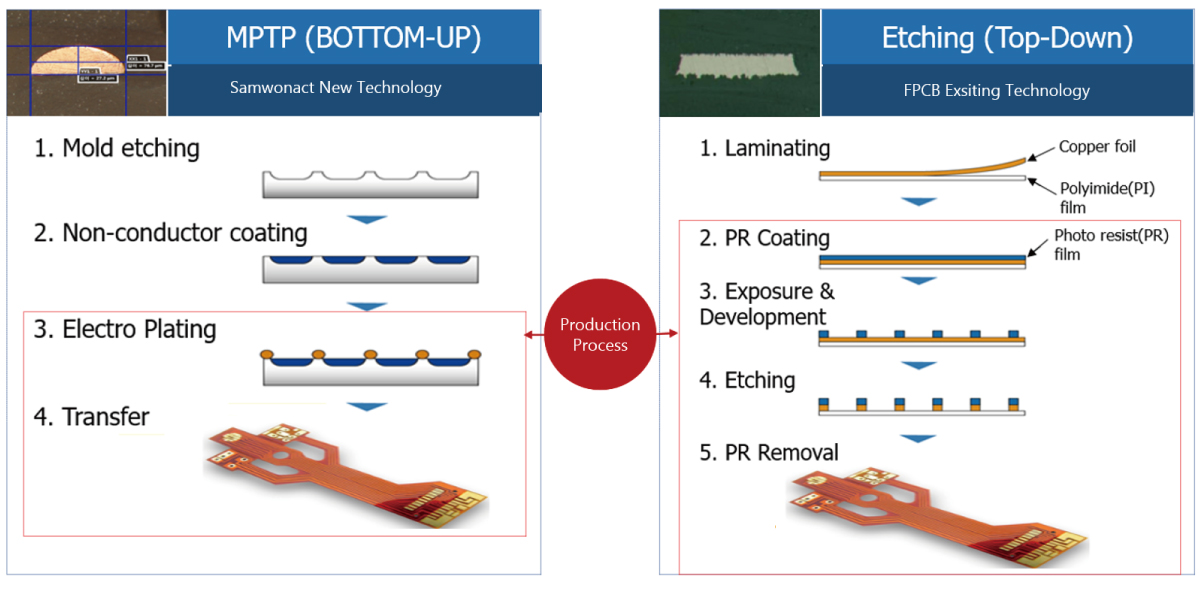

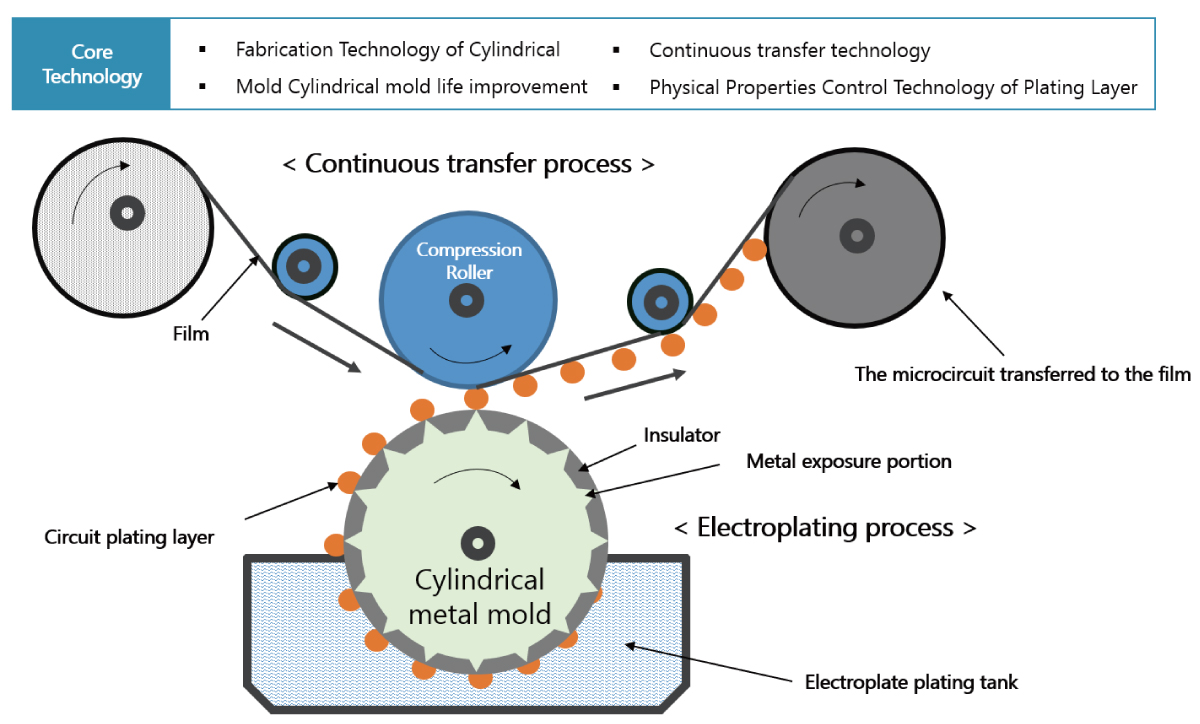

MPTP Technology Overview

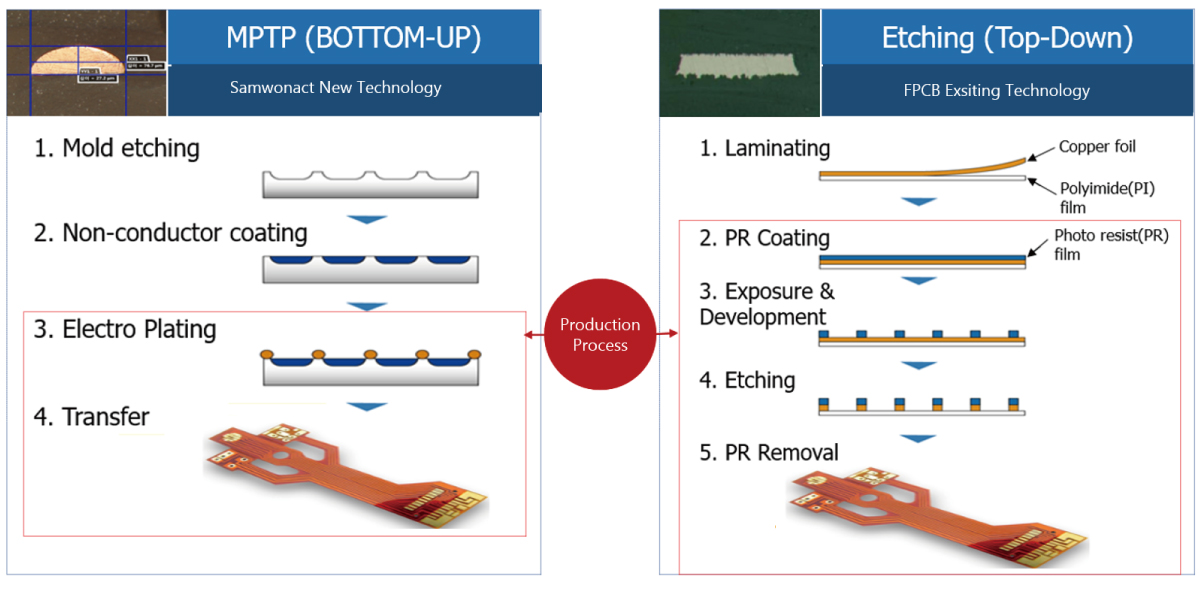

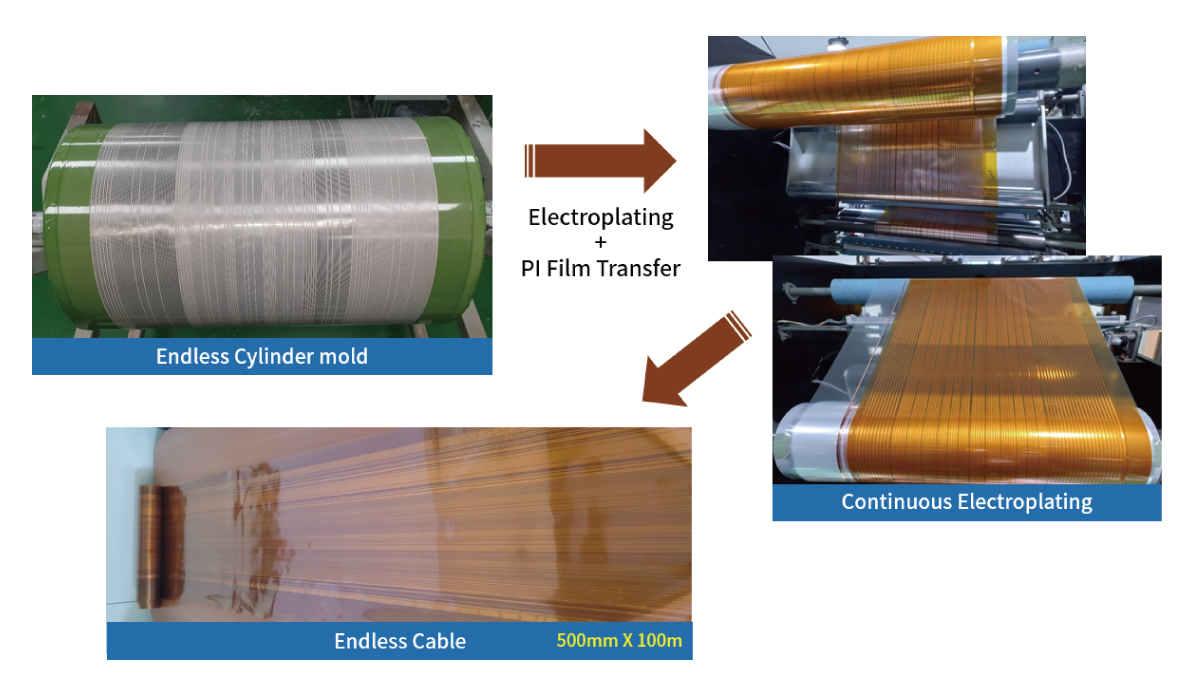

1)Unlike the existing etching process of FPCB, a metal mold is manufactured and plated only on a fine pattern formed on the metal mold

by electroplating, and a fine pattern

manufactured using a flexible film is transferred to form a fine pattern on the film.

2)Successfully commercialized for the first time in the world, replacing the existing FPCB manufacturing process.

3)New technology that is different from traditional FPCB manufacturing processes.

Differences Between MPTP and Etching Technologies

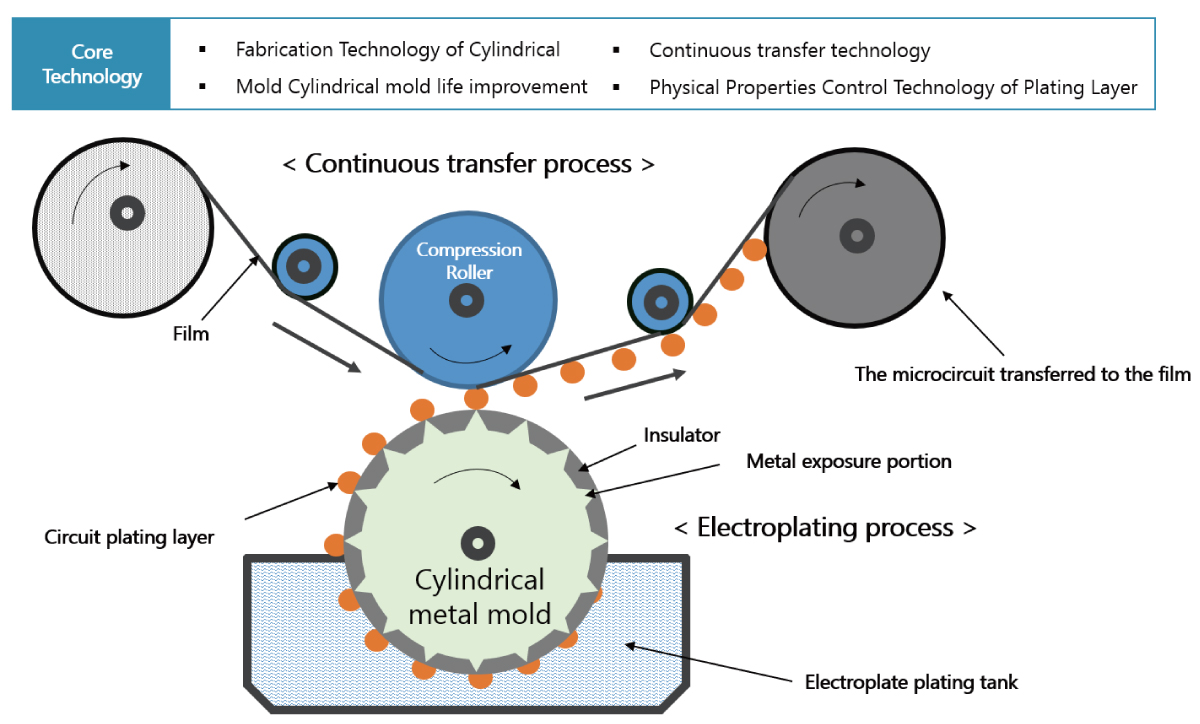

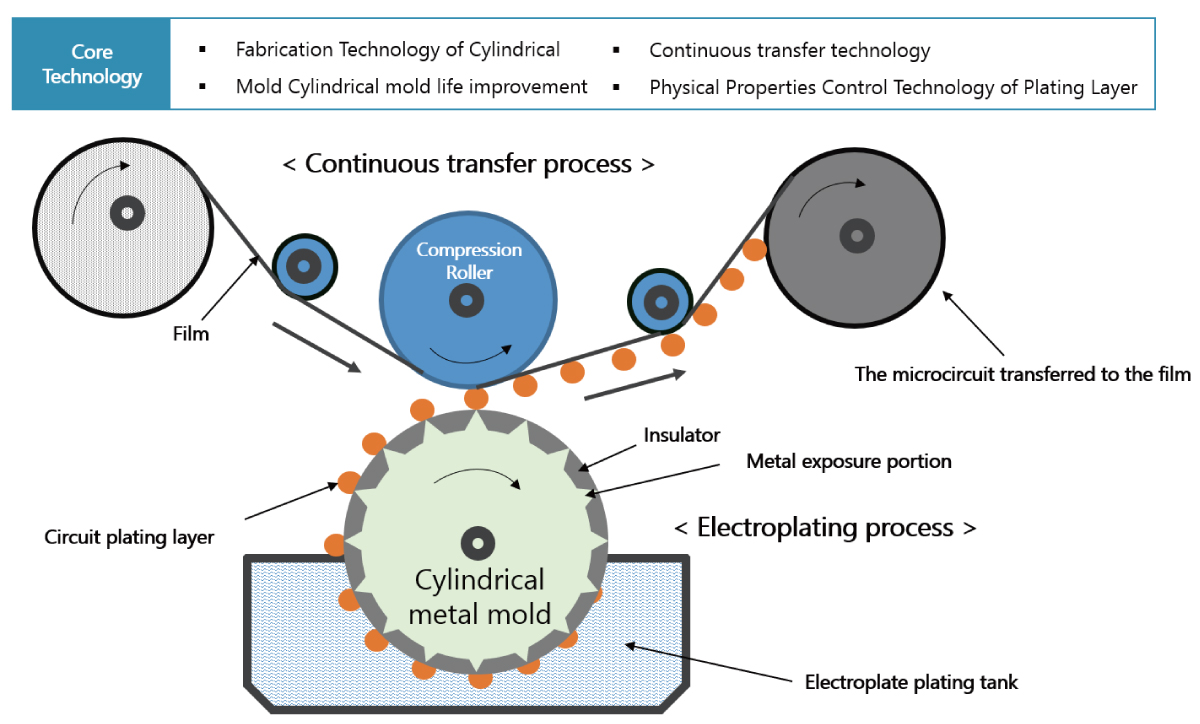

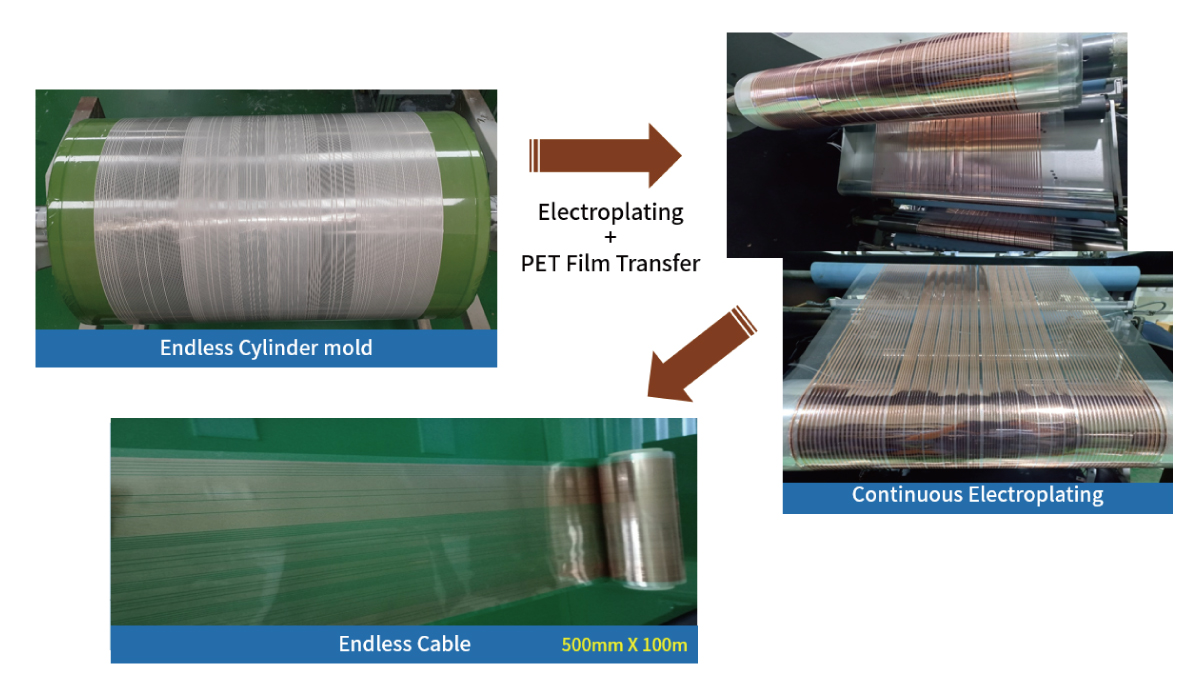

MPTP Core Technology - RTR

MPTP Technology Characteristics

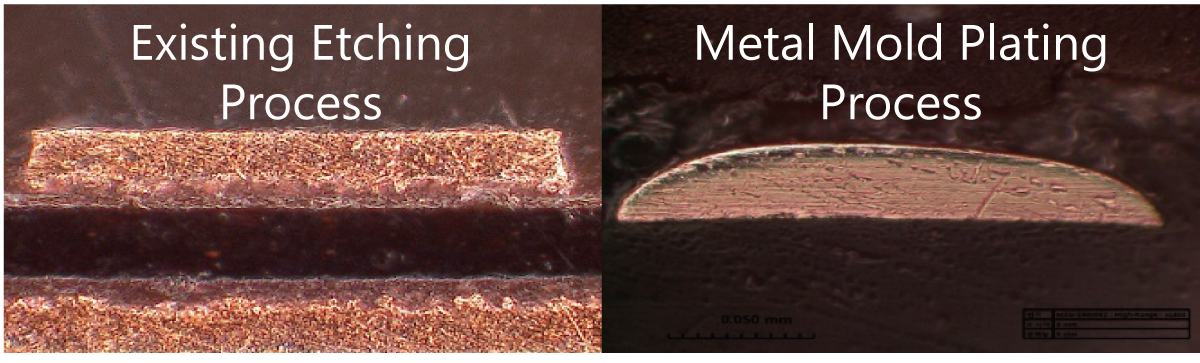

1)Circuit Cross section shape

- Existing Etching Process: 4 Sided Angle

- MPTP Electroplating : Arch

- Shape favorable for ultra-high frequency signal transmission in the GHz band

2)Control circuit properties

- Alloy plated circuit can be formed (Electrical resistance, strength adjustable)

- Multi-layer circuits can be formed (Circuit properties can be adjusted)

3)Scalability

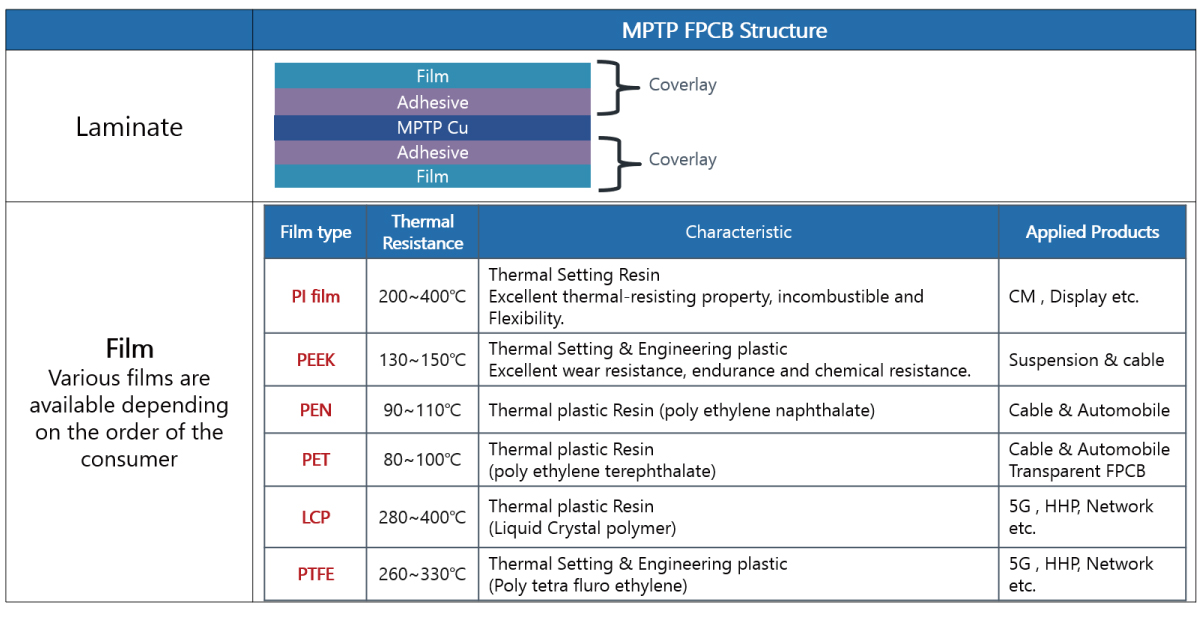

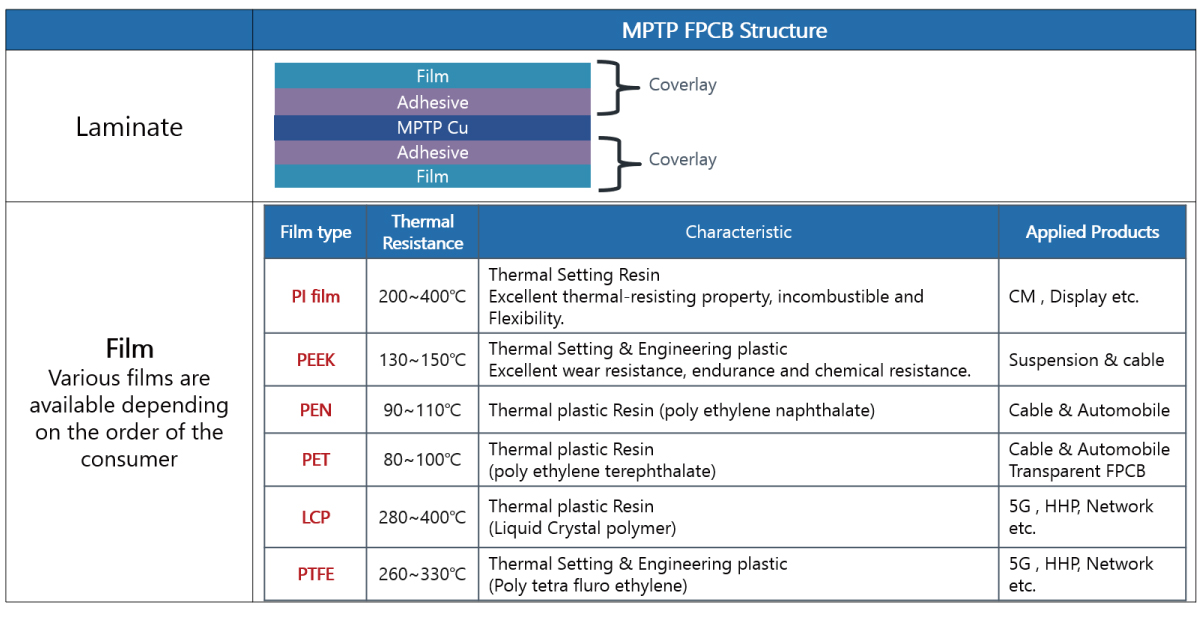

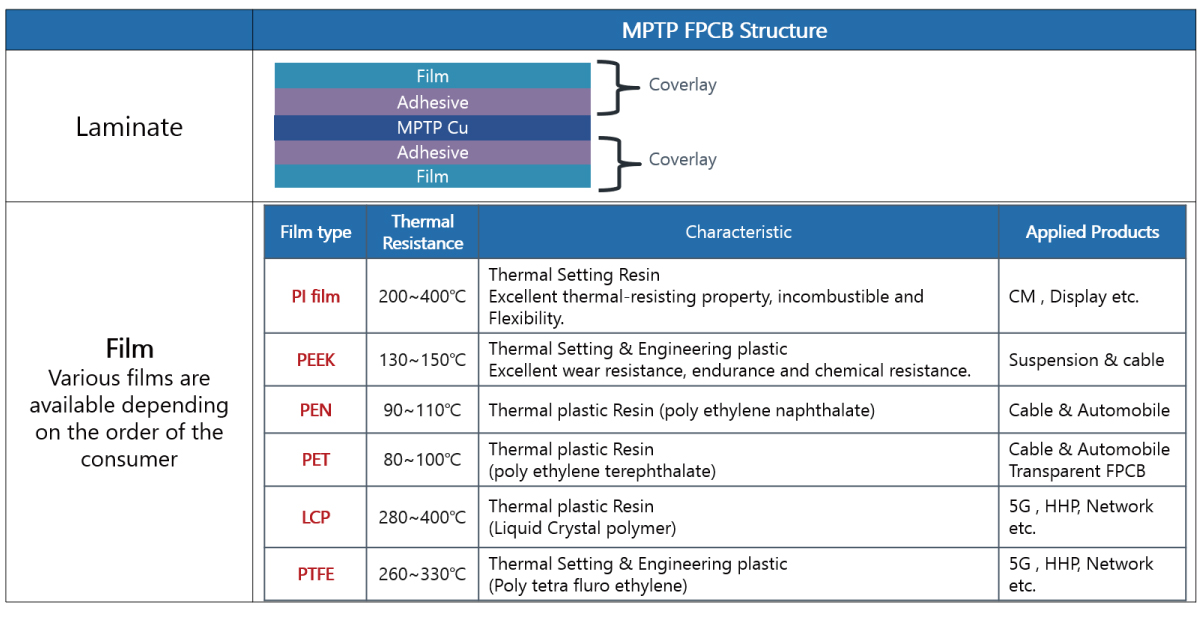

- Applicable to various films other than polyimide

- Optimal combination of low permittivity film and adhesive(5G Communication Cable)

- Can be applied to a variety of products when combining circuit properties with transfer film

4)Cost competitiveness

- Sheet mold batch type: 20% cost reduction

- Continuous production of cylinder molds.: 40~50% cost reduction

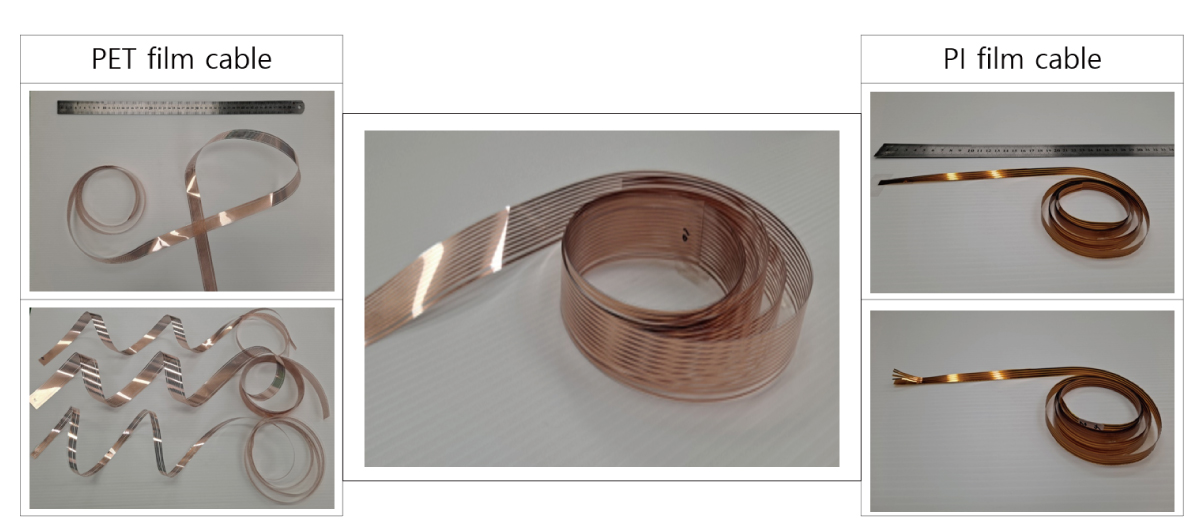

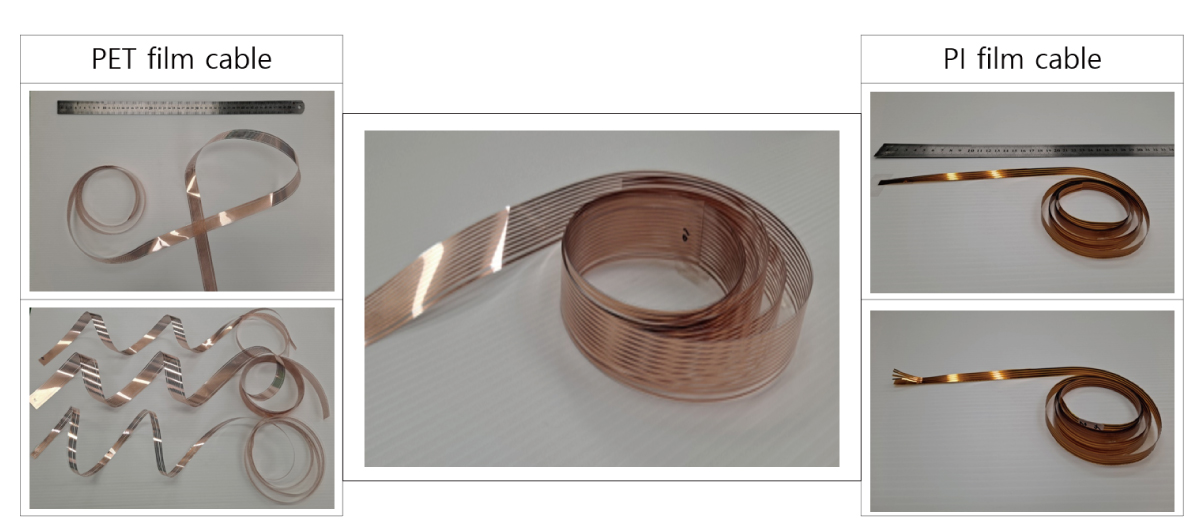

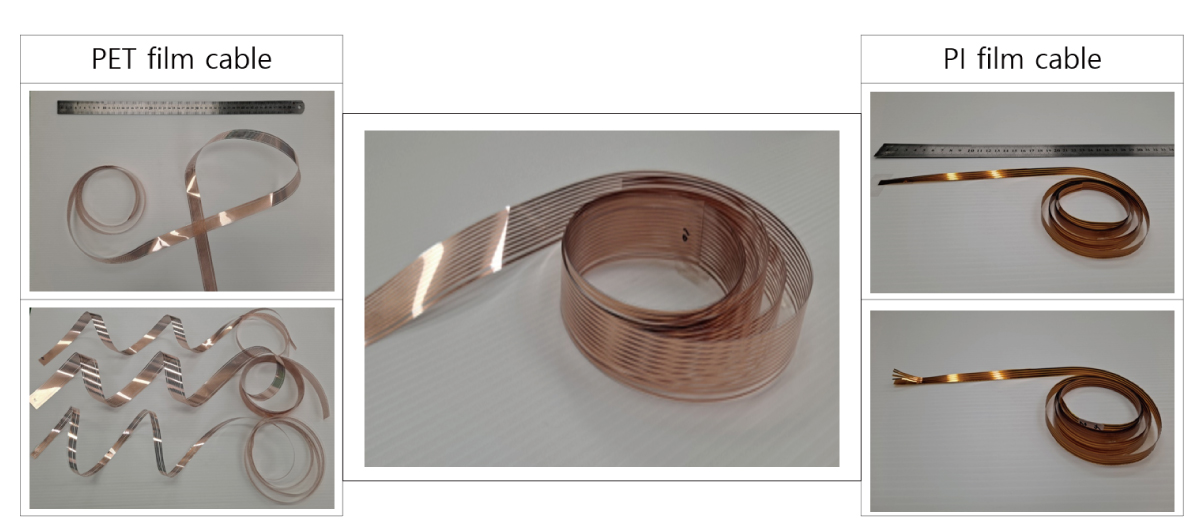

MPTP Strong Point - Various film selections

Flat Cable Technology Application test

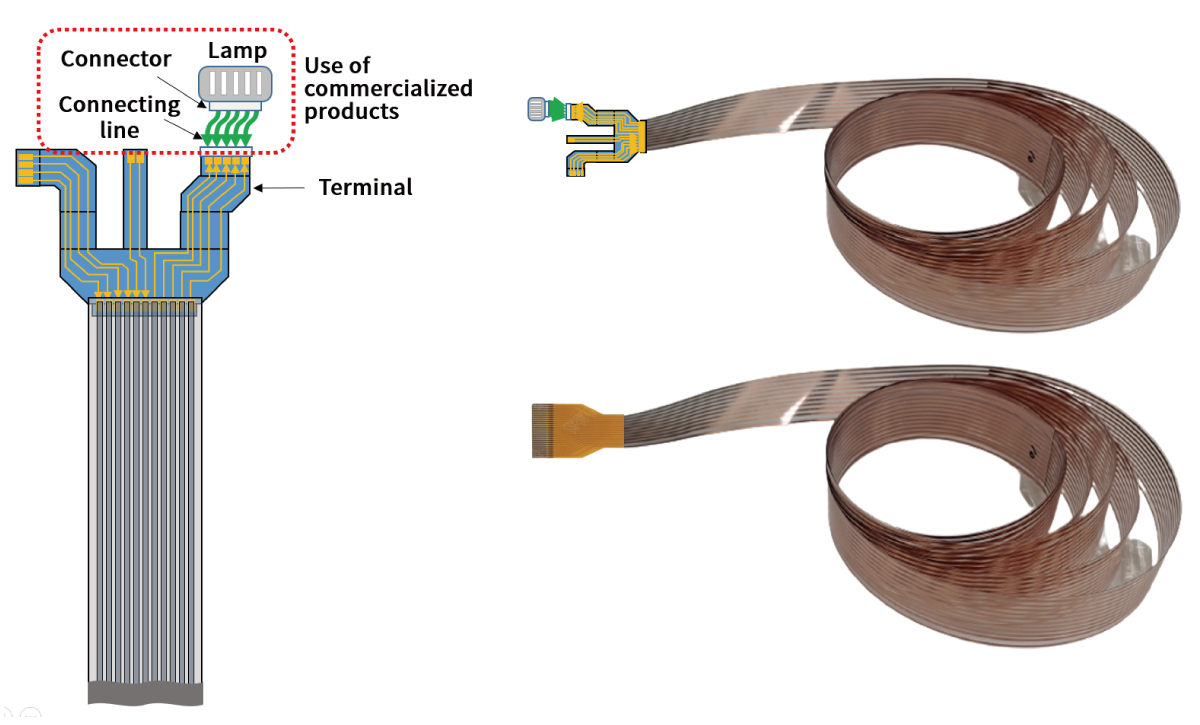

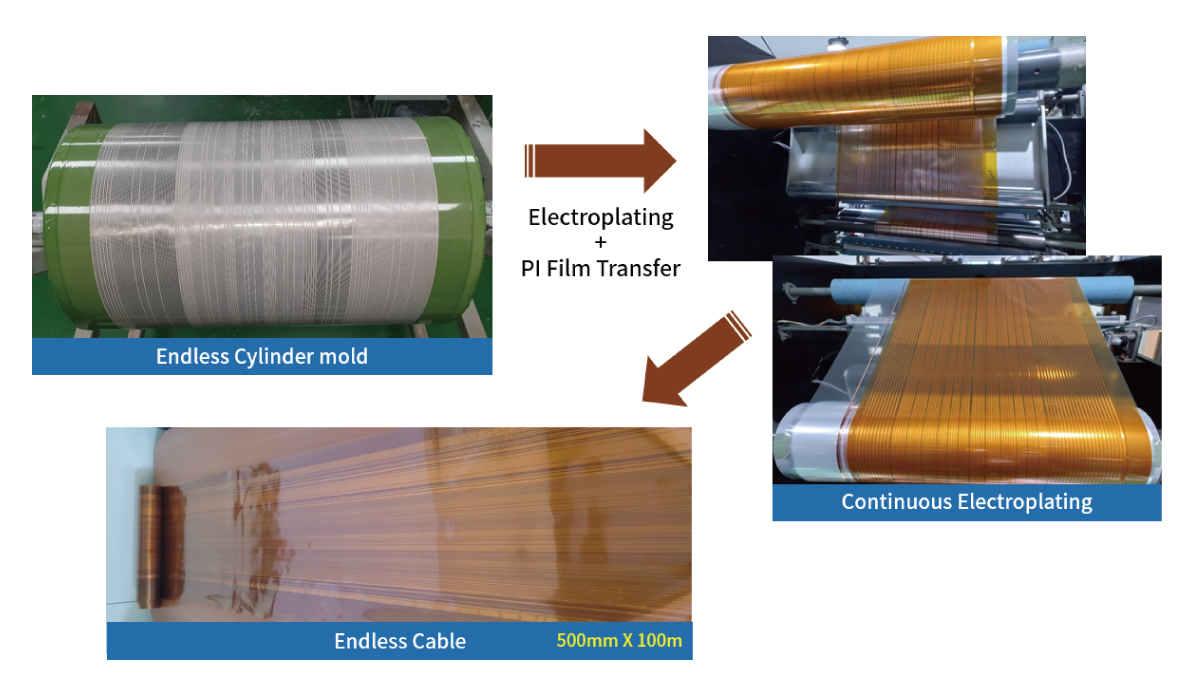

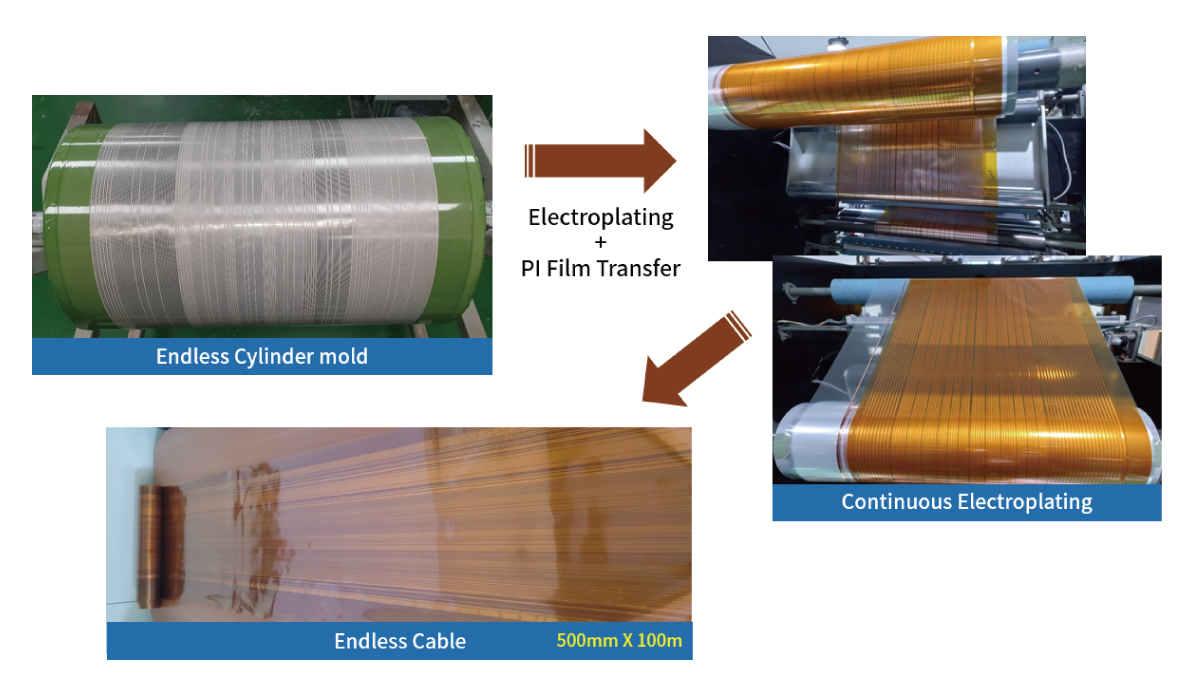

Endless flat cable on PI film by continuous electroplating process

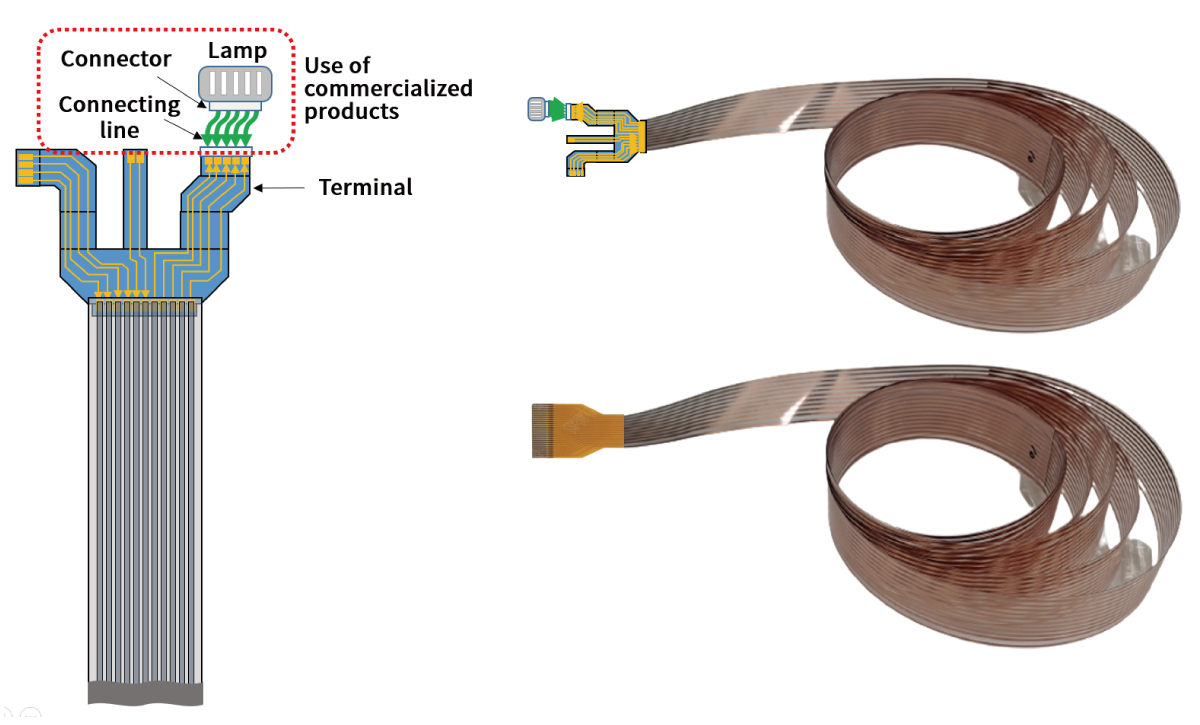

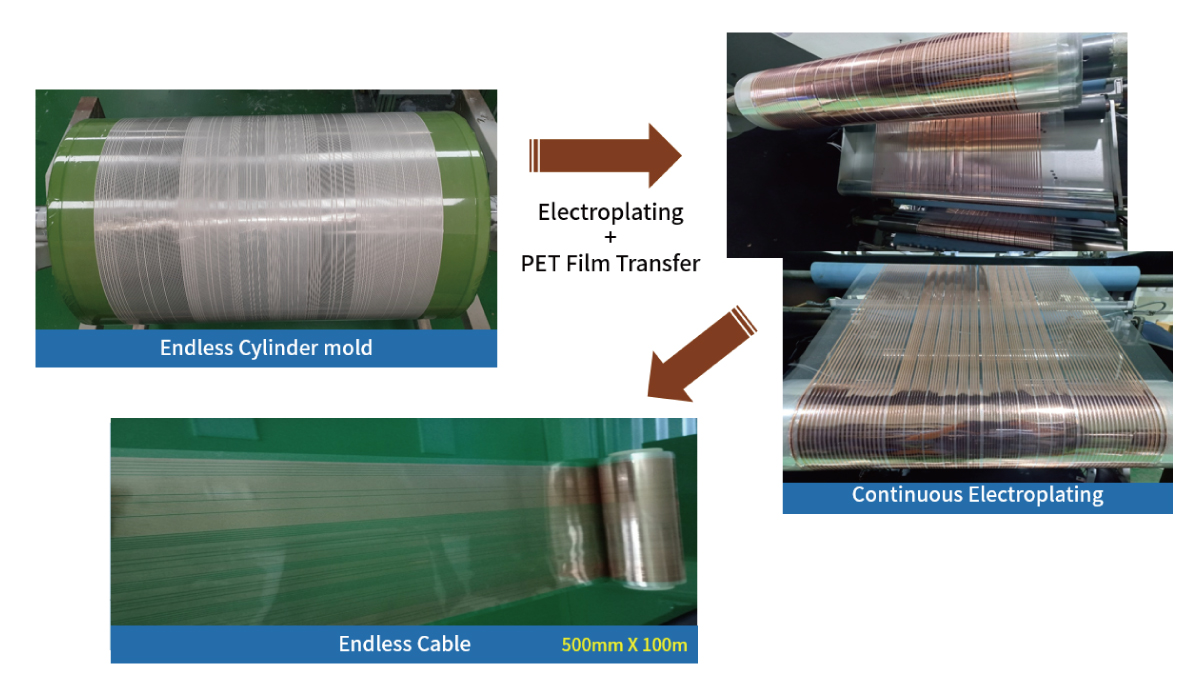

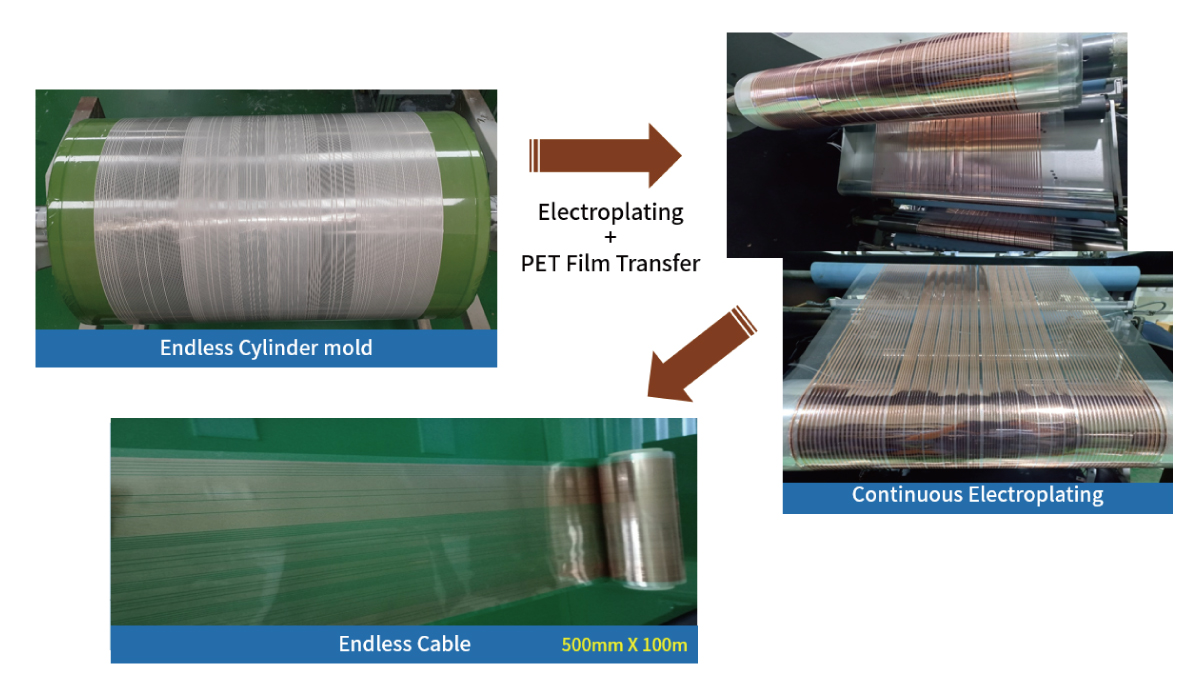

Endless flat cable on PET film by continuous electroplating process

Slitted endless flat cable

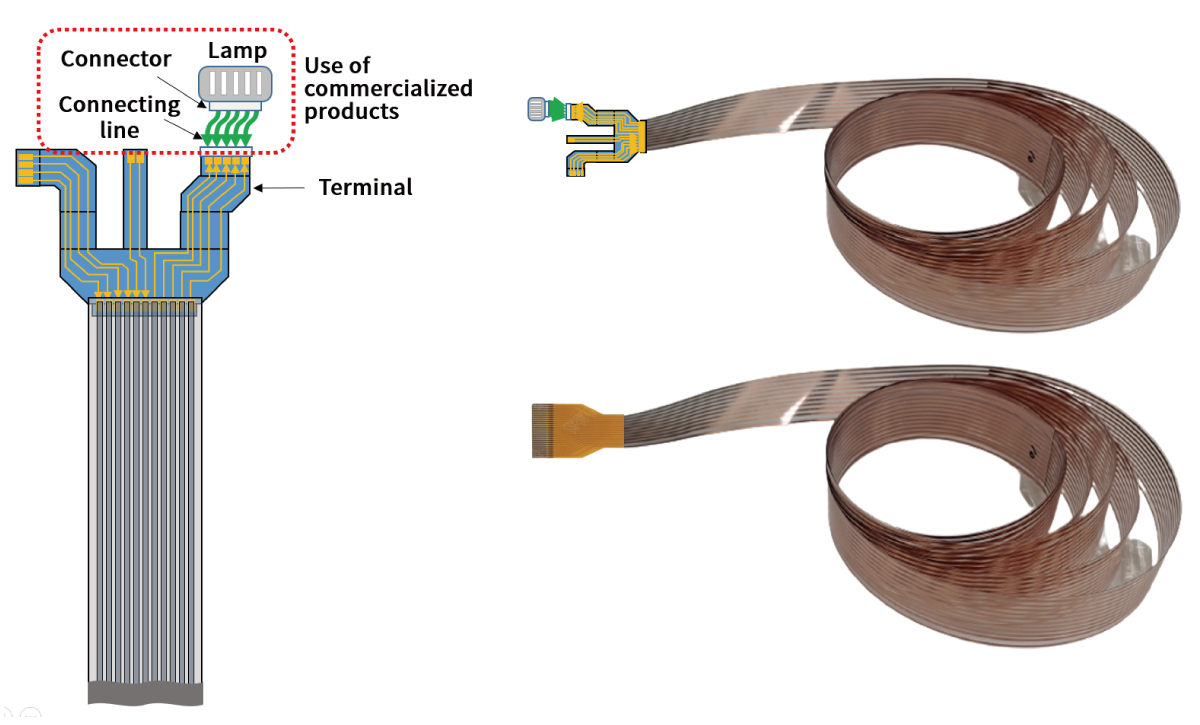

Concept of flat cable connector